TPO roofing materials introduction

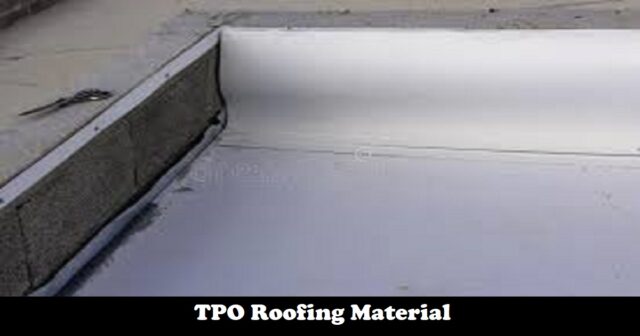

TPO stands for Thermoplastic Polyolefin. Most people are familiar with a special kind of bright white single-ply roof typically installed on low slopes or flat roofs and are popular for commercial purposes. TPO roofing is this form of roofing. This kind of roofing is now among the most often used ones in both commercial and residential settings. These are single-ply membranes that can be synthetic and of rubber-type material.

If you have a flat roof or a low-slope dormer in your home, TPO flooring can be a good option. It keeps the room below the roof cooler and protects from direct sunlight in summers. It can be used over a room that is not a home, such as a garage or covered patio. One of the well-known types of commercial roofing is single-ply membrane. However, there are several other types according to budget and facility. TPO roofing membrane sizes are commonly available in sizes 10, 12, or 20 feet wide. These sheets are rolled up to use in commercial facilities. So, choosing the material that fits according to rooftop style, budget, and customer needs is always preferable.

This article highlights many important features of TPO roofing materials. It elaborates on the need for why they are used in home and commercial spaces. Also, this article will be part on the installation of roofing materials, the different pros and cons of roofing materials, their advantages and disadvantages, and their types.

The function of TPO roofing material

So why is roofing necessary for your home? You must first understand why TPO roofing is used after learning about it. A roof or roof facet with a pitch of less than 2:12 is referred to as low slope (less than two vertical units up for every 12 horizontal units out). Water won’t drain from a flat or low slope roof on these slopes as quickly as from a more excellent pitch. Hence it must be waterproof. Because asphalt shingles aren’t designed to hold standing water, you cannot utilize them.

A TPO roofing material or membrane can be installed on low slopes or flat roofs. Here are some of the points why TPO material is better to use on home roofs.

● TPO roofings are considered relatively cost-effective compared to other roofing options like PVC.

● TPO roofing membranes also remain good in terms of energy-efficient roofs. TPO membrane-made roofs effectively reflect solar heat, preventing it from entering your building and cutting down on the energy required to heat it.

● When compared to numerous other roofing kinds and materials, TPO roofing membranes are also very durable. They withstand damage from ripping, water, bacterial growth, dirt, and moisture buildup quite well.

Types of TPO roofing material

Single-ply is a commonly known type of this commercial material.

There are two main types of TPO roofing materials based on chemical properties, which are;

● Thermoplastic Polyolefin (TPO)

● Propylene Diene Terpolymer (EPDM)

Thermoplastic Polyolefin (TPO)

Thermoplastic polyolefin, called TPO roofing, is a single-ply roofing membrane. It is made of rubber polymer from two chemicals, polypropylene, and ethylene. It can be mounted in mechanically attached systems that have an open ceiling. TPO is more durable and can last up to 20 years than other types of roof membranes. TPOs come in a range of thicknesses. 45 and 60 mils of thickness are typical.

Ethylene propylene diene monomer (EPDM)

Worldwide, low-slope buildings are the main application for EPDM, a highly resilient synthetic rubber roofing membrane (ethylene propylene diene terpolymer). It is an alternative to PVC for flat roofs in the Bowie area. Its two primary components, ethylene, and propylene, are derived from oil and natural gas. The market offers EPDM in a range of widths, from 7.5 feet to fifty feet, and in two unique thicknesses, 45 and 60 mils. Both white and black versions are offered.

TPO and EPDM roofs each have a life expectancy of roughly 25 years.

To know more about ‘Garage Door Panel Replacement’, read this article: Garage Door Panel Replacement: A Definitive Guide About Garage Door Panel Replacement in ‘Home Improvement’ category.

TPO roofing material: Pros and Cons

The pros and cons of employing TPO materials for roofing homes are listed below.

Pros

Hot air guns weld a TPO roof, so they are not only flexible but strong material.

● The TPO membrane can reach Underwriters Laboratories (UL) Class A fire resistance certification by adding fire-resistant chemicals.

● TPO materials are generally white; therefore, they are highly reflective materials that reflect UV and sun rays.

● For a number of reasons, TPO roofing materials are also regarded as green building materials.

Cons

● Seam failure is the main problem that might result from a poor TPO product.

● Some TPO materials can’t withstand high temperatures, and some TPO products are vulnerable to failure when exposed to heat for a lengthy period.

● Not all TPO is made equal, and producers frequently alter their compositions to achieve the best outcomes at affordable prices.

● The narrow width of TPO’s rolls, a common concern, is another issue. It can lead to problems like additional seams at different locations on the roof’s surface.

Installation of TPO roofing material

TPO has a unique installation process that differs from other roofing materials. The TPO membrane is normally fastened to the roof deck with mechanical fasteners and plates.

Hot air welding is used to join the TPO’s overlapping membranes together. In addition to being incredibly flexible, strong, waterproof, and uplift resistant, hot air-welded seams are also winded uplift resistant. The roofing contractor softens each TPO membrane with a hot-air welding gun. It is also called a plastic welder or hot gas welder. It also presses the two together with a roller to create a strong seam.

Final words

This article elaborates all about TPO roofing material. If you wish to eliminate any moisture or water from the roof’s surface, TPO roofing is a great choice. You can acquire a professionally finished TPO rubber roofing by considering various factors like cost-effectiveness, thickness, UL ratings, etc. For installing flashing onto your home’s roof, always seek the advice of a qualified roofer.

Frequently Asked Questions (FAQs)

Apart from this, if you are interested to know more about Garage Door Panel Replacement then visit our HOME IMPROVEMENT category.